Meet the Yankee

Meet the Yankee

This article is transcribed verbatim from the November, 1967, issue of Flying magazine. Although it's subject to their copyright, I hope they won't mind this reproduction with full credit. the subject airplane is the common ancestor of the entire general aviation "Grumman" line. It's hard to imagine that this plane and its "children" have been with us for over 50 years.

by James Gilbert, senior editor

photography: Bud Loader

In general aviation circles few announcements caused as much stir, aroused as much interest, and set as many pilots' hearts apounding as did the statement from Mr. James R. Bede of Cleveland, Ohio, in the year 1963 that he had built and would shortly produce an airplane for the common man. It was to be a Volkswagen of the sky. Two-place, with folding wings, with a speed of 130 knots (150 mph) for the 108-hp version and the price was to start at a mere $2,500 for the 65-hp version. Orders rolled in from around the world. Thousands of them. Many contained deposits. It seemed the answer to a pilot's dream.

It was

drizzling this golden-olive evening over Lake Erie, but on a nice day

you can slide back the canopy and fly along open-cockpit style. The

unorthodox castering nosewheel is an innovation borrowed from homebuilders.

It was

drizzling this golden-olive evening over Lake Erie, but on a nice day

you can slide back the canopy and fly along open-cockpit style. The

unorthodox castering nosewheel is an innovation borrowed from homebuilders.

In fact Jim Bede had built an airplane, the BD-1. It was a little low-wing two-seater with a single tubular extruded spar and folding wings. It had glass fibre spring gear legs and very extensive use of bonding and honeycomb structures. It was the kind of airplane of which schoolboys dream, such as do not have to face the reality of actually bonding such structures, and then getting them past the caustic gaze of an FAA inspector.

Not daunted by such harsh realities, Jim Bede looked around for backers to build his baby and soon found a group of eager Ohio industrialists who came forward with a half million dollars to build a plant and move into production with the BD-1. Jim was hired as president of the new Bede Aviation Corporation and a super new factory was quickly begun at Cuyahoga County Airport. Jim confidently promised FAA certification of the BD-1 within the year. By June, 1964 to be exact.

For the next 18 months Jim Bede's supreme enthusiasm, more intoxicating than any drug, carried the corporation along. He and his 15 engineering staff dreamed and schemed, imagined and created till you might have thought that like the mad scientists of comic strips they were planning to take over the entire world. But certificate the BD-1 they didn't. Ideas poured from them like rain from a summer shower; in such a heady atmosphere it must have been difficult to apply oneself to such a mundane task as getting approval from the dull old FAA for last year's little airplane.

Finally in August, 1965, came the inevitable day of reckoning. Jim Bede's backers called a meeting to see what 18 months had achieved. In concrete terms, it seems, very little; they had no certification prototype, and they had been almost totally unsuccessful at bonding. They had been successful only at publicizing the project. And they had spent over that 18 months more than a million dollars, and the man from the FAA (whom somebody had thoughtfully invited to the meeting to temper Jim Bede's optimistic conviction that certification still was lurking just around the corner) told them they were hardly nearer gaining that magic piece of paper than they had been 18 months before.

It cannot have been a happy meeting. By the end of it Bede was out, and most of his engineering staff with him.

But replacing Jim Bede was to prove nearly as impossible a task as taming him. For a while a Cleveland industrialist called Fred Lennon ran the company (see flying, November 1965). Then a man named Jim Frey was found; he had been production chief at a huge company making railroad cars, had retired before his time, had always been interested in airplanes. He came in October, 1965, and by all accounts did his best, but the whole madness of the operation defeated him in time, and by midsummer 1966 he was gone.

And so we come to Russ Meyer, today's incumbent, and one unlikely guy to be running an aircraft business, for although an ex-military pilot, he's a lawyer by trade, and a young one at that – just 35 years old. Mind you, he didn't exactly jump at the job when it came up.

"I was extremely busy at our law firm here," he'll tell you. "The Bede Corporation had been using a law firm in Toledo. It's a bit unwieldy trying to represent an out-of-city client, and when at the end of 1965 they wanted to refinance through debentures, they came to our firm and I got the job. My first job was the refinancing. Then they wanted me to be general counsel, then in April, 1966, secretary as well."

He must have done a good job, because soon he was asked to step in and run the company. He refused; he was happy at his law firm, and secure there. But in the end he took leave of absence from the law firm to put his client's house in order.

"There's really no rational reason why I'm here," he'll tell you, laughing the while with some secret inner glee.

You might think that picking Russ Meyer to run things was a last-ditch stand by the company's backers, and you might be right at that. But Russ Meyer has such a dogged determination to get things done, such a concern for detail, such a blinding honesty in appraisal of the problems of the hour that he might well be the man to bring it off. For a start, he got the airplane certificated, in August this year. It wasn't easy.

Says Russ of the months preceding certification, "We had people who brought hammocks out here and slept with the airplane. I can remember feeling guilty leaving the factory to go home at three in the morning. When we flew the first certification prototype in February of this year, everybody was out there lining the runway – like in the old movies. I don't think I've ever had a year quite like it."

The problems of certification, the problems that defeated Jim Bede and that he left behind, the problems that Russ Meyer all innocently inherited, are problems you would hardly believe. At first it seemed to Russ that the bonding that in the BD-1 completely replaces rivets was the principal problem. It is a tacky process that requires that the parts to be bonded be first acid-etched and rinsed (using four different tanks) before the adhesive can be applied, then held together with a pressure of at least 10 pounds per square inch and heated to 250 degrees for one hour while the bond cures. Later the bond is examined with an ultrasonic fault-detection device.

There are simpler room-temperature bonding techniques (this was how Jim Bede built his first prototype BD-1). but they require a curing time of six to seven days and lack the strength and lightness required for a production airplane.

It was after the previous regime had failed to bond six fuselages in a row that Meyer had first showed his true mettle. He requested help from the chief engineer of the Whittaker Corporation in California to help put them right, and within a month they had successfully bonded three fuselages. One can imagine how such a get-things-done ability was grabbed at by the Bede Corporation's owners.

The company is in a very real way pioneering new structural construction techniques, and you can imagine how tough on them the FAA is. Everything has to be tested and stretched and pushed and vibrated and fatigue-tested well beyond any shadow of reasonable doubt.

Even the horrors of bonding, Russ was to discover, weren't the worst of what he was facing. Soon after he took over, a qualified test pilot ran a flight evaluation on the airplane and found there was plenty wrong with that. It was way down on performance; it was slower than Jim Bede had claimed (he'd never even had the ASI calibrated), it wouldn't climb as fast, it had a tendency to fall over at the stall but wouldn't roll much at any other time, it was deficient in longitudinal stability, the control system was overly complicated and there were clearly going to be problems when it came to spin testing.

It seems that Jim Bede's exuberant optimism and unconcern with trifles had run away with him; Bede's brochure figures for his airplane included an empty weight of 812 pounds and a cruise speed of almost 130 knots (150 mph), but his prototype weighed 984 pounds and cruised at nearer 108 knots (125 mph). How 172 pounds weight was going to be engineered out in manufacture was not explained.

So they worked at it: they added a bungee in the elevator circuit, and redesigned all the control circuits and enlarged the ailerons and put horn balances on the tail control surfaces and added a trim tab. They lengthened the wing and gave it a new tip and dropped the idea that the wings should fold. They changed the shape and size of the gear. They redesigned the fuel system. And in the end they had an airplane to which the FAA would give its blessing.

And next, as if to show how things were changing around Cuyahoga County Airport, they renamed the enterprise the American Aviation Corporation, and the BD-1 became the Yankee.

The total investment today, from all parties, is slightly less than $3 million, for which the corporation has as tangible assets the factory, worth maybe $500,000, and that frail but costly piece of paper, the FAA type certificate for the new Yankee. Russ Meyer foresees a need for a further $6 million over the next three years to get the airplane into production, with a paper profit being achieved late in 1970, at the sale of around the 1,500th production airplane. His production plans seem ambitious; from a factory that stands echoingly empty and void of bustle today he sees 132 Yankees being turned out next year, 550 in 1969 with production rising to 75 a month by the end of that year and reaching a total of 1,200 in 1970.

He's already ordered about $95,000 worth of machines, has begun tooling and is working on such mundane but necessary tasks as clearing trees for car parks and installing sprinklers. He aims to have about 50 employees by the end of the year, and to hire new men at the rate of 15 a month thereafter.

Can Russ Meyer sell Yankees in those numbers? He thinks so, and has priced the airplane at $6,500, to be exactly $500 less than the Cessna 150, over which it has a nine-knot (11-mph) speed advantage at cruise. Manufacturing airplanes is a business where you must run hard merely to stand still, and one wonders how long Cessna (or Piper, or anybody else for that matter) will let him get away with that sort of thing unchallenged. It will be a battle.

Marketing plans include three direct factory dealers to be appointed by the end of this year, one each in New York, Texas, and California, and 12 more next year. And he is choosing them with some care.

Having won the certification battle, Russ Meyer's next task was to find himself some key executives. He ain't done badly, either; Dick Kemper came from Cessna to be general manager of operations, and Meyer picked up a chief engineer, a chief of structures, a chief of quality control and a director of purchasing from the same source. Larry Kelly, his director of marketing, came from Aero Commander.

Meanwhile, across the field, barely half a mile away, Jim Bede sits in his office or in the coffee shop downstairs, still dreaming dreams. He is no longer plotting to take over the world but just to fly around it, nonstop, solo, in a powered glider whose cockpit has the finest row of warning lights you ever saw, including one labelled antigravity.

"I have the greatest respect for Russ Meyer," he'll tell you with becoming generosity.

And the American Aviation people have kind words to say for him. "If it hadn't been for his imagination in putting the prototype together and his salesmanship," said one, "we'd none of us be here today."

Yet happily all this love in the air doesn't prevent Bede telling you frankly where he feels he new regime is going wrong. He still maintains, stoutly, that when he left they were only six months away from certification. He still maintains that it would have been possible to manufacture the BD-1 with the 108-hp engine for $4,500. Talking to him you begin to see that he is a man whose besetting sin is overoptimism, and such a refusal to be daunted by problems that sometimes he cannot come to grips with them because he simply cannot see that they exist.

"Why does the word 'impossible' have to be so overpowering?" he cries in a voice approaching anguish. To him it clearly isn't. And that talent for self-publicity continues to get in his way. Of his round-the-world project, one American Aviation executive said sourly, "He's issuing press releases daily. Hourly."

To Bede the problems that gave his successors such sleepless nights are mere trifles, hardly worth bothering with. Of his BD-1's slow rate of climb and sluggish cruise he says, "Just a couple of little things needed doing." Of the difference between prices, his $4,500 and their $6,500, he says, "There isn't anyone over there who knows how to estimate cost figures." Of the spin recovery problems he says, "Just a small inch-and-a-half plate in the right spot of that fuselage, and you can recover whenever you want." Of the abandonment of the folding wing idea as impractical he says, "It's just a $20 item to make them fold."

How can you argue with such a man when he refuses to see that there's anything to argue about? And of the performance figures he claimed for the BD-1, he says with passion, "I can show you articles on the original airplane by completely independent writers who went up in the airplane and saw the cruise speeds." (We can show you such an article in an old copy of flying, but the writer did note that "the indicator on this airplane was so far off as to be completely misleading.")

Meanwhile, back at the American Aviation ranch, Russ Meyer, the battle to certificate the Yankee won, is well on top of the next skirmish, to find the key executives he needs. He can look forward to the headaches of improving his prototype, the anxieties of keeping his stockholders behind him, the Herculean task of equipping his factory to turn out Yankees at ever increasing rates and ever decreasing cost. He'll be busy some little while yet.

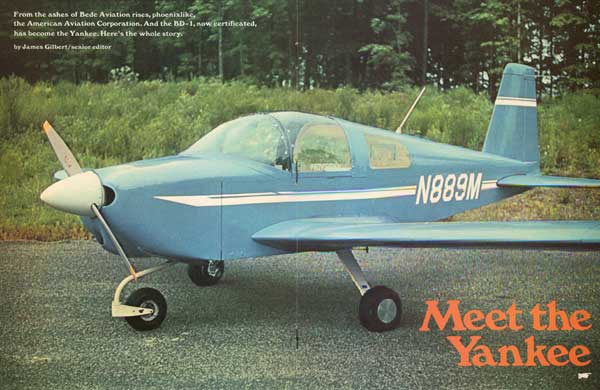

The Yankee, when you come to look at it, is a chunky, boxy little airplane, a sturdy, cheeky-looking machine, simple and slab-sided. Compact. Beautiful? Let's say functional. Come closer, and that sailplane-smooth wing draws your eye, and you glance over the rest of it. No rivets. Not a single dragging rivet to be seen.

Hop up over the wing and settle in your seat. Hmm. It's roomier than the 150. There's a solid structure separating the two seats much like the transmission tunnel of a ford Thunderbird, mounting a huge throttle that looks for all the world like a gear shift. Also the flap lever, which looks like no flap lever you ever saw before.

Grasp that throttle, and you feel it deserves an afterburning J79 behind it, instead of a little old 108-hp Lycoming. This throttle incorporates its own friction lock, so that it stays where you leave it until you unlock it by starting to move the throttle lever. It is a great throttle lever. On the production airplane it may be replaced by one of those stupid plunger things. Pity.

Start up. It's 80 degrees or better outside, so we leave the canopy half open and taxi away breezy as two motorcyclists. (I am flying with Dick Kemper, general manager of operations.) The nosewheel is in no way connected to your feet, and swivels free; you taxi therefore on the brakes, with all the maneuverability in the world. In any crosswind you must carry a soupçon of brake on the downwind side so as not to weathervane, as though you were a sailboat. It's fun!

Now both Dick and Russ Meyer have told me there are a number of things they propose to put right before production, and one of them is the noise. In the air it's mostly engine noise, but adding to the clattering hooves of 108 horses as you taxi along is a tendency of all those areas of unsupported skin to "oilcan," so that it's a bit like driving along in a mechanical wobbleboard, if you are familiar with that unique Australian musical instrument.

Ah, the takeoff. This, for accuracy and neatness, requires some light juggling with the feet, because of the non-steerable nosewheel. You start with full right rudder and some pretty firm right brake. After you've gone about 70 yards, you start reducing the right brake, until quite suddenly the rudder comes to life and you must look lively on that. By about 61 knots (70 mph), the airplane is ready to fly, so come back on the yoke, but not too hard or you'll leap into the air in all of a dither, with the stall warner yelling in protest. It takes three or four trips around the field before you get it off exactly, but you feel a rich emotional satisfaction when you can do it.

Best rate of climb is well along at 74 knots (85 mph). the book says 900 fpm, but we indicate nearer 650 fpm, and a timed minute of climb tends to confirm this. But the 900 fpm is at sea level on a standard day, so today the heart is powerfully affecting things.

The Yankee has two miniyokes like sculptured arms flexing heir biceps, and there's a deal of lost motion in the aileron circuit, but this cannot hide how nice the controls are. A stick will be an option on later Yankees.

The climb to 8,000 feet to check the best cruise speeds is a long one, and as we get there the rate of climb is down to 250 fpm. We level off, leave full throttle, and slowly accelerate to 105 knots (121 mph) IAS, with the RPM stabilizing a hair over the 2,600 redline. The noise is awesome, and conversation is only possible at the level of a shout. Some later shuffling with the slide rule back on the ground, and correcting for the two mph that the ASI is reported to be slow, gives us a TAS of 122 knots (141 mph) for about 79 percent power.

This accords most favorably with the brochure cruise speed of 115 knots (133 mph) at 75 percent. Some other settings: 2,500 rpm gives 97 knots (112 mph) IAS or 113 knots (130 mph) true; and 2,200 rpm (which is about 50 percent and the approved long-range cruise setting) gives 77 knots (89 mph) IAS or 90 knots (104 mph) true. Now 133 mph at 75 percent is creditable enough, and some 11 mph faster than the Cessna 150.

Longitudinal stability is good, and the airplane will fly by itself in calm air, but roll in a little bank and let go and she quickly winds up in a real tight spiral. Most light airplanes have no better than neutral spiral stability, and there are others besides the Yankee that are unstable in this way – the Bonanza for one. Spiral stability is a function of dihedral and fin area, and the FAA is very exercised as to whether airplanes should be required to have it, or at least an artificial form of it such as a wing-leveler like Mooney's PC. There is even a notice of proposed rulemaking out on the subject. Spiral instability is of little import except to noninstrument pilots who find themselves suddenly in cloud. Then it is deadly.

We throttle back to investigate the stall. Whenever the RPM passes through 1,500 there is a burst of oilcanning, and the whole airplane sings like George Harrison's sitar. The stalls are preceded by a slight buffet and a powerful horn. There is only a slight tendency to drop a wing, and excellent aileron control at all times. The stall speed, 55 knots (64 mph), is fast for such a small airplane. (The 150, for example, stalls at fully 13 knots or 15 mph less with full flap.) I note that the Yankee stalls a mile or two below the bottom of the arc on the ASI, which tends to confirm that it is indicating a mile or two slow.

We descend to 2,000 feet, noting and approving of the very high never-exceed speed, 170 knots (195 mph). For those who cannot be bothered to climb up to 8,000 feet to get the best cruise, we record at 2,000 feet and 2,400 rpm (which is about 73 percent), 105 knots (121 mph) IAS or 110 knots (127 mph) true.

We make some touch-and-goes, noting the excellent visibility from that bubble canopy all around the pattern. We find that the flaps are notably ineffective (they are also on the list of things to be improved before production), and that an accurately straight landing requires the same kind of nifty footwork the takeoff did.

With those nice controls and the high redline speed, the Yankee cries out to be certificated in the aerobatic category. It seems the decision was made to go for the normal category when flight testing revealed that some redesign would be necessary for it to meet the extra aerobatic category spin requirement of recovery inside one and a half turns after a six-turn spin. Aerobatic certification is on the program for the future.

But for the present there is the Yankee, a sporty, swift and satisfying airplane with a lot of what the competition doesn't have. The price is right and the prospects are good that after years of promises the little two-place airplane that was the BD-1 will be produced and delivered into the hands of the waiting market. It will not have many of the features that an unrealistic Jim Bede vowed would be there but in retrospect it is improbable they ever would be, at least at the price quoted.

It will have all the modern features that a most realistic Russ Meyer feels can be safely and economically engineered into an airplane. And if there are many differences between the two airplanes there are many differences between the two men. While Bede dreams and scoffs at reality, Meyer has moved to the threshold of success in short order.

And how big will that success be? Only you can tell. If you are one of those who placed you order in the old days you will receive preferential delivery treatment if you want a Yankee. And if you're just a pilot with a yen to have a snappy little two-place runabout that can give you lots of pleasure for not too much cash, get in line.